Over the last two years, U.S. legislators have given out over $2 billion in grants and loans to companies for the research and development of energy efficient green technologies for the nation’s auto industry.

A major motivator is fear. The latest government report - The Recovery Act: Transforming the American Economy through Innovation - found that, “Oil powers 95 percent of America’s cars, trucks, ships, planes, and rail cars.

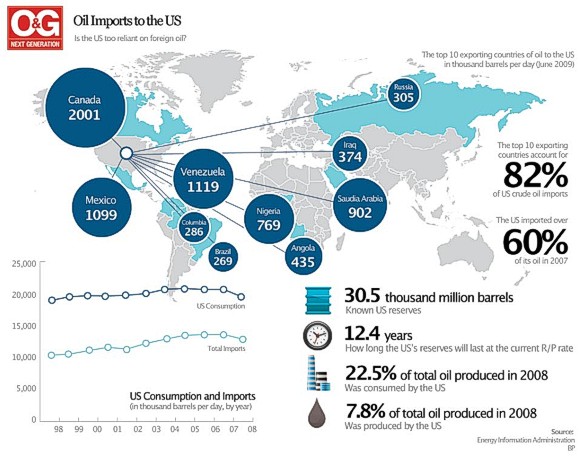

“The United States is the largest oil consumer and importer in the world and relies on imports for more than half of its oil consumption. This dependence on oil is an energy security threat and increases U.S. economic vulnerability.” Additionally, it acknowledges that, “The environmental impact of petroleum-powered vehicles is also a rising concern.”

The bulk of the grant money to the auto industry has gone into building factories and facilities for improving electric vehicles, new battery technologies, electric power trains, and the development of charge stations.

The report speculates that, “Today, an American driving 32 miles a day to and from work will spend almost $1,000 a year on gasoline, each day adding to U.S. dependence on foreign oil. A consumer driving an electric car would save over $630 per year powering the car with electricity generated in American power plants instead of gasoline made from imported oil.”

Among the notable recipients to receive funding from the Recovery Act is Telsa Motors. On the high end, the company makes a handmade, carbon fiber Roadster that can accelerate from zero-to-100 kilometers in less than four seconds without consuming petroleum. The Roadster plugs into any conventional socket and can travel over 394 kilometers on a single charge. The company touts that it’s a sports car “that can be charged with solar, hydro, or wind energy.

Highway-capable electric Telas Roadster. Photo courtesy of popularmechanics.com.

Highway-capable electric Telas Roadster. Photo courtesy of popularmechanics.com.

The Roadster was also just approved for Japan’s Clean Energy Cash Rebate Program, which is amied at promoting the accelerated adoption of electric vehicles or plug-in hybrids. It’s the country’s only qualified import vehicle. Each Roadster which starts at about $153,000 or 12.8 million yen is eligible to recieve a cash rebate of up to 3.24 million yen or approximately $38,000 at current exchange rates.

The price is far too steep for most of consumers, but Tesla says it plans to use much of the newly received loan money toward its goal to “produce increasingly affordable electric cars to mainstream buyers.”

The Recovery Act funds are also helping increase the financing of companies like UQM Technologies Inc., which develops and manufactures electric motors, generators, and power electronic controllers for the automotive, aerospace, military, and industrial markets. With the new financing, UQM, which has long-built only custom prototype parts, is now also planning to expand its manufacturing capacity to build electric power trains at high volume.

On the commercial driving side, last May, Navistar International Corp., a Lisle, Ill. manufacturer of commercial trucks delivered its first electric trucks supported by a grant from the Recovery Act. These plug-in powered trucks can carry more than two tons of cargo a distance of up to 100 miles per charge, according to the company, which received $39.2 million in funds.

Electric-powered FedEx truck manufactured by Navistar. Photo courtesy of overoll.com.

Electric-powered FedEx truck manufactured by Navistar. Photo courtesy of overoll.com.

Navistar plans to produce 400 electric trucks, which will be powered by nanophosphate lithium ion batteries manufactured by A123 Systems (also a Recovery Act recipient).

A123 Systems just opened a new plant in Livonia, Mich., which the company expects will expand its manufacturing capabilities by up to 600 megawatt hours per year when fully operational. The company also says it plans to focus on manufacturing prismatic cells and systems at the new facility.

This new plant is designed to enable the complete production process, including research and development, manufacturing, cell fabrication, module fabrication, and final assembly of complete battery packs ready for vehicle integration.

A123 Systems says that it also plans to open a coating plant in Romulus, Mich., which it expects to come on line during the first half of 2011. David Vieau, president and chief executive officer of the company, said in a statement, “Over the next several years, we expect to create thousands of jobs in greater Detriot and plan to contiue our expansion in the area as we do our part in helping the U.S. emerge as a global leader in the production of advanced lithium ion batteries.”

Beyond vehicles mechanics, companies such as ECOtality North America are receiving millions in funding to develop charging infrastructures. The company has been awarded a $99.8 million grant from the U.S. Department of Energy as part of a plan to deploy nearly 15,000 charging stations in 16 cities located in six states (Oregon, Washington, California, Arizona, Tennessee and Texas) and the District of Columbia.

More specifically, this year, charging infrastructures will be deployed in the following cities: Phoenix, Tucson, Ariz., San Diego, Los Angeles, Portland, Ore., Eugene, Ore., Salem, Ore. Seattle, Nashville, Tenn., Knoxville, Tenn., Chattanooga, Tenn., Washington, D.C., Dallas, Houston, and Fort Worth, Texas.

Reader comments and input are always welcomed!